Food & Drink

Delicious – Docker Bakehouse and Brewery

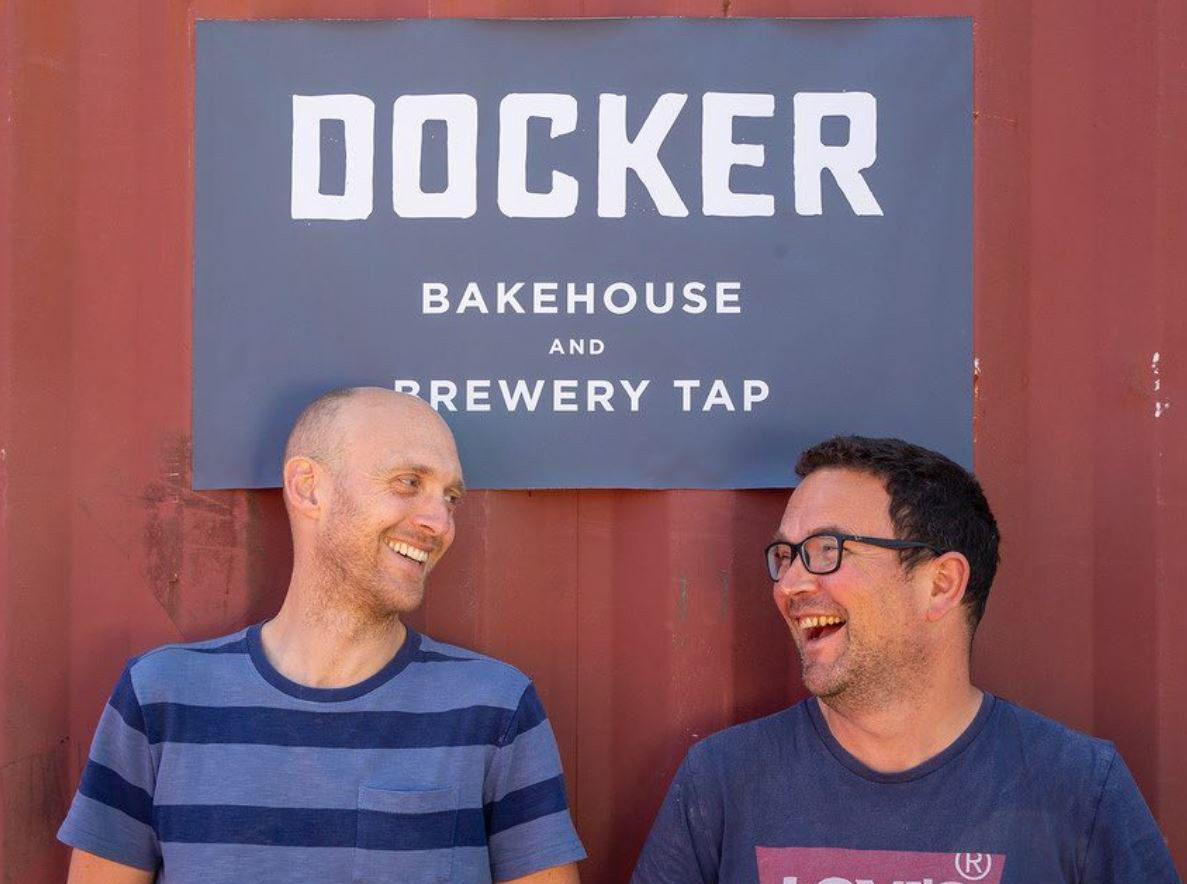

Docker Bakehouse and Brewery started off in a container on Folkestone’s Harbour Arm in 2016. Founders Wes Burden and Pete Nelson have grown the business so well that beer and bread production has moved to larger premises, the latest on Park Farm in Folkestone. Their produce can be bought at various locations in town. Folkelife joined Wes and Pete to find out about the origins of their business.

Avid home-baker

Wes: “I’ve been an avid home-baker for many, many years, making sourdough. I’d done some courses and people liked the bread I was making. At the same time, Pete and I were having fun doing some home-brewing, and we thought we’d try and make a business of it. Even if it was just a side project to our normal work, we’d have a go and see what would come of it.

“We were both in computing, design for the web and print and so on; not working together, but in the same industry and friends. Docker was an opportunity to get into the real world of working with physical products, and maybe a simpler life. We didn’t have a grand plan, we’d baked our first loaf, and made our first bottle of beer. We thought we’d give it a go with minimum outlay to see if it was something we wanted to pursue.”

Pitfalls of working in a shipping container

The duo got a container at the Harbour Arm and, with their second-hand brewing and baking kit, they started to produce a few loaves to sell to the public, and the bread-side took off straight away.

“We had no windows in the container; we had to prop the door open in the wind to stop it slamming! It was very basic with no insulation, which is a big factor when making bread. You struggle against the fluctuating temperature when baking bread, it makes it tricky to get a consistent product. We had coping mechanisms – well, literally a fan heater to keep things warm in the winter, and the door open and fans to cool us down in the summer! Heat is as much of a problem as cold really – we aim for the dough temperature to be 24 degrees, and if it’s 23 it’s noticeably slower, and if it’s 25 or 26 you’re like ‘woah! Panic! This is going really fast!’ So you need to put it in the chiller to cool it down. Insulation is key!”

Beer production

Pete: “We sell our beer in kegs for local pubs and restaurants, and in cans. The cans are a great way to keep the beer fresh, daylight doesn’t alter the product and it’s easy to transport. But, when the pubs shut due to Covid-19 we realised we had to adapt and make a product that people could consume at home. Our production of canned beer has increased incredibly. Now we’re making around 4000 cans a month. 60% of our sales is in cans, 40% in kegs, and I am very proud of the places that serve our beer.

“Since we started Dockers it’s been clear that people want to support small producers which serve their local area. The bread side of things can’t be done at a huge scale, and with the beer here, we’re at a production stage I’m happy with. Moving and expanding does take a lot of energy. And, if you look at the size of the fermenter Wes and I used at the start, to this one we have now, it’s the same process. It makes sense to size up, because it takes the same amount of time to make 60 cans in our small fermenter as it does to generate 3000 in this.”

feeding the five thousand

Wes: “I remember our first day baking around 20 to 30 loaves, a small amount because we didn’t want to waste it if it didn’t sell. But then it sold really quickly! That was quite embarrassing! From there it grew organically, and became pretty clear that we needed to separate the brewery from the bakery in terms of manufacture.”

The team has moved through its second home and onto its third in the Riverside Craft Centre in Hythe. Both the bread and beer are produced on the same site, with the possibilities of sharing a canning unit with Hop Fuzz and a cider producer there. It also means that they sell over 2000 items a week across their bakery range a week.

slowly the flavour grows

Wes: “The sourdough process takes 2 and a half days. We start at 4.30am where someone comes to bake the bread from the previous day. The doughs are made up the day before and we put them in the chiller. They prove slowly and the tasty goodness grows overnight. We get that baking, and also roll some baguettes to bake that day too.

“Someone comes in at 6 am and starts the doughs which are going to be processed that day, for baking on the following day. There’s normally someone in at 8am too, so we have these overlapping shifts. Someone is here until 4pm, finishing and tidying up, and getting the starters ready for the next day.”

Folkestone’s fabulous sourdough

The nature of sourdough baking is that there is time for the starter to ferment. That’s the key difference, it makes the bread more digestible.

Wes: “You don’t get such a bloated feeling from eating it. It’s more nutritious as the nutrition in the flour becomes more accessible once it’s been semi-digested by the fermentation process. The dough develops a lot of flavour, and lasts longer as it doesn’t have all the additives in it. Our classic white sourdough is just flour, water and salt – that’s it! So you’ve got this incredibly simple, but nutritious, and very tasty thing from just simple ingredients, a bit of time, and care. A commercially made loaf, I think, takes an hour and a half from mixing it to it being put in a bag – there’s no fermentation happening, it’s risen very quickly with fast acting yeast and in a very warm environment. With us, it takes around 36 hours. In my opinion, that’s the sort of time it takes to make bread properly.”

naturally occurring yeast

“The yeast in our starters is naturally occurring yeast, and bacteria that all play into the nice mix of activity. You can get different strains of yeast and bacteria and that’s all in the flour – so the flour is key.” And they get through more than half a tonne of flour a week.

DFL – Down From London

DFL has been one of the most popular Docker beers they’ve made. There’s always room to play around and try new products, and there will be room on the taps to show off what’s been fermenting.

Pete: “I think there’s been an expansion in the beer market because of a new category of craft beer. American Pale Ale is a great product using fresh ingredients and live product. It’s served cold with more carbonation. That style has been pioneered in the US and has come this way, to the UK, rather than the other way round. It’s been rapidly growing in popularity in London over the last 10 years, and so our DFL – Down From London Pale Ale is a play on bringing that style to Folkestone.”

Locally sold

“I am incredibly proud of the locations in town that sell our beer. They’re the people who really know about how to look after and serve beer properly, so you know it’s being treated well. Space Bar always has a line of DFL. Lucky Chip does too sometimes; we did a Tap Takeover there which was fun! The Beer Shop sells our beers and The Chambers has our cask beers. Brewing Brothers on Beachside at Folkestone Harbour has our beer too, so we’ve come full circle.”

A little bit of Folkestone history

The team don’t like waste – no business does – and Wes admits that Docker has a reputation for selling out of bread. If they do have any left-over then it goes to the Rainbow Centre, Folkestone’s local support network for the homeless. KRAN – the Kent Refugee Action Network, also benefit from any extra loaves.

“We run schemes where our customers can pay for a loaf of bread and it will be donated to the Winter Shelter. It’s been so successful that we’ve ended up supplying them with bread for the 3 months the Shelter runs over the winter.”

Working in the real world

Since the start of Dockers in 2016 there’s been a huge growth in the business. Pete and Wes want to make sure there’s a decent offering for the public, which is where they can be creative and experiment with making different products. With all the early mornings, and huge customer demand for bread and beer, are there any pangs to return to the old job…?

Wes: “I don’t ever find I want to return to my old job stuck at a computer. I do go back to it occasionally, as my Dad runs the business I used to work for. It’s nice to use your brain in a different way, and that’s nice to dip your toe back in but I very soon realise why I don’t do it anymore! I enjoy doing something physical, it sits with me better. Dockers is more ‘real world’. I like that.”

Pete:“Both Wes and I used to work in computing, and you can certainly make more money in that industry than this. What I like about doing this is that we’re creating products that people care about. Docker beer and bread seem to connect with people in a more emotive way than computer programming. You get a more fulfilling customer satisfaction with this product!”